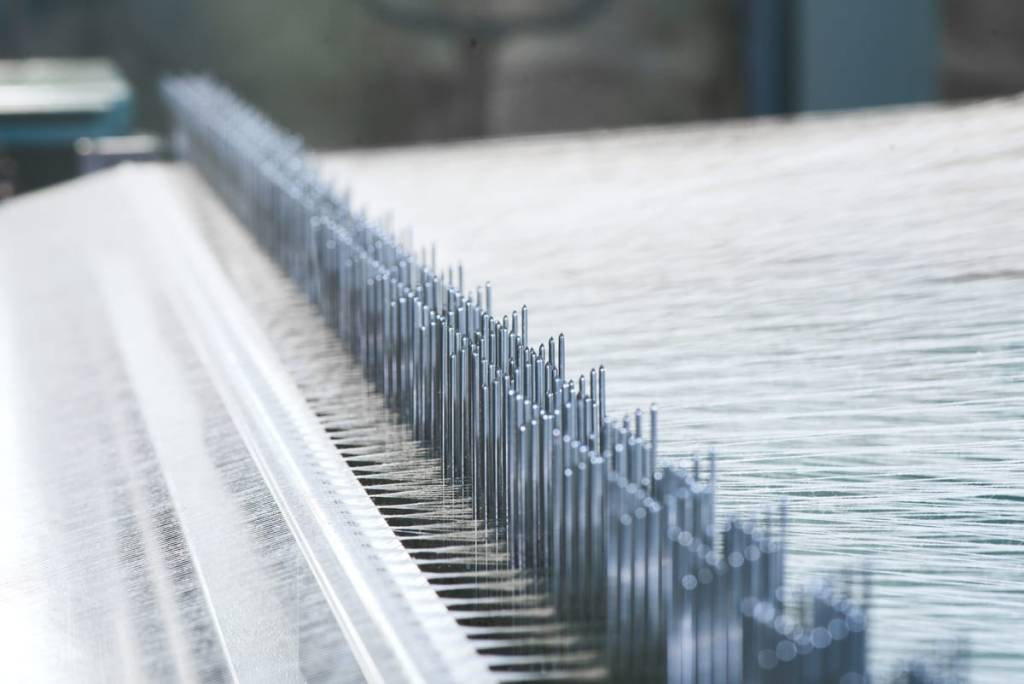

Our weaving division is the heart of our operations, where innovation meets tradition to produce fabrics of exceptional quality and durability. With a focus on precision and attention to detail, we employ advanced weaving techniques to create fabrics that exceed industry standards.